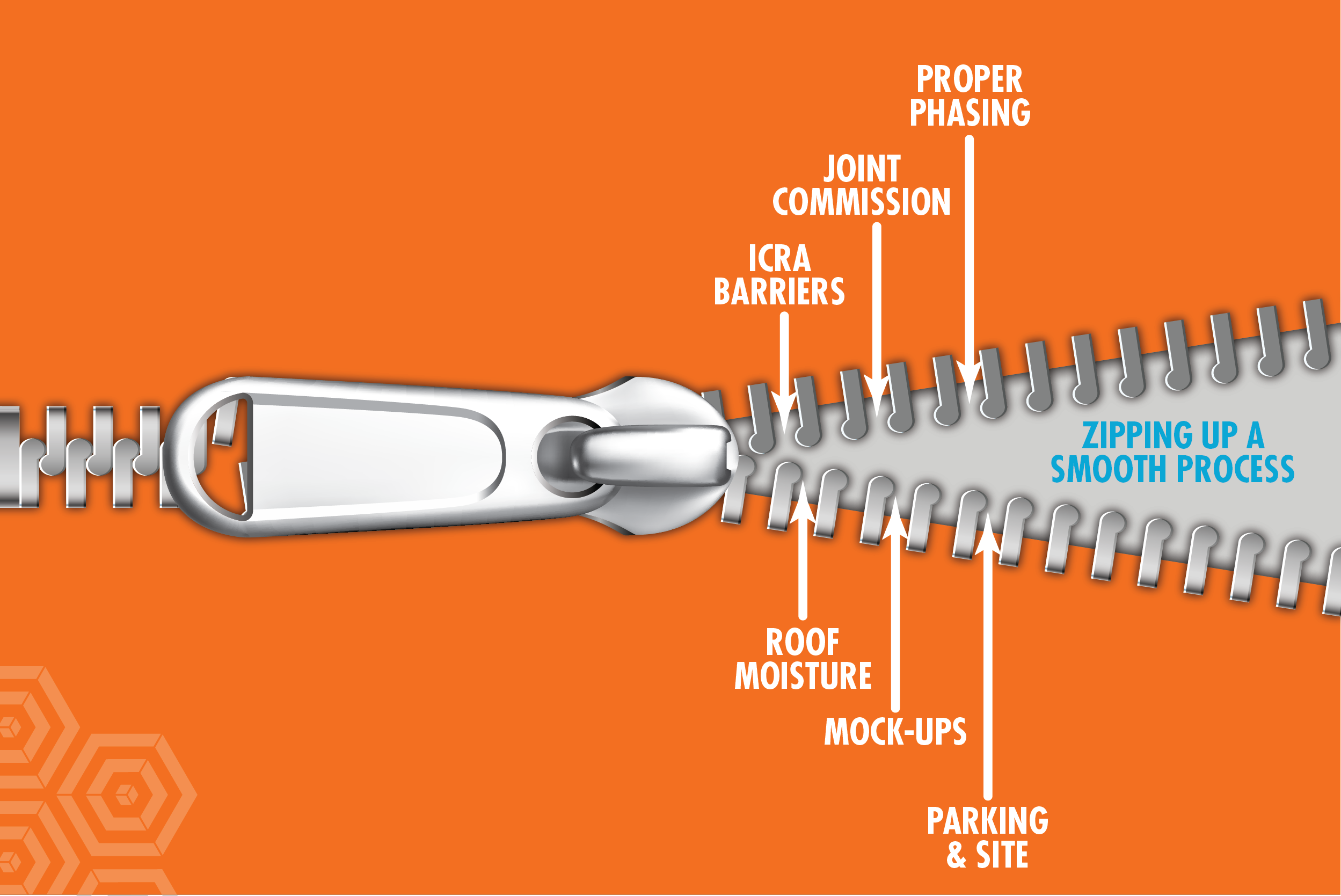

6 Essential Tips for Healthcare Owners During Construction: Insights from Architects & Engineers

By Megan Yoder, RA, EDAC

September 12, 2023Post Tagged in

|

When healthcare projects are passed from designers over to the General Contractor for the start of construction, the transition should be seamless for all parties at the table, including the owner. However, as many healthcare facility managers know all too well, this becomes a new fast-paced chapter, sometimes filled with “growing pains” for their maintenance team, vendors, and staff. As an advocate for the owner, architects and engineers at Design Collaborative have plenty of experience with this shift of focus. Once the groundbreaking is complete and shovels start flying, there are a few key items to launch the first discussions in the jobsite trailer on day one.

|